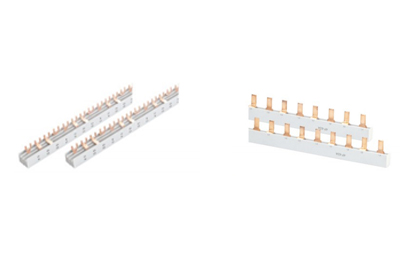

In electrical power distribution systems, MCB (Miniature Circuit Breaker) busbars play a pivotal role in efficiently channeling electrical current. The choice of material for these busbars significantly impacts their performance, durability, and cost - effectiveness. Here, we explore the characteristics of the commonly used materials in MCB busbars.

Copper

1.Exceptional Electrical Conductivity: Copper is renowned for its outstanding electrical conductivity. It has a low resistivity, which means that it allows electrical current to flow through it with minimal resistance. This property results in reduced power losses during the transmission of electricity. In a large - scale industrial power distribution system, using copper busbars can lead to substantial energy savings over time. For example, in a factory with high - power consumption, the low - resistance nature of copper busbars ensures that more of the electrical energy generated reaches the machinery, rather than being wasted as heat due to high resistance in the conductors.

2.High Thermal Conductivity: Along with excellent electrical conductivity, copper also has high thermal conductivity. This is beneficial as it helps in dissipating heat generated during the flow of current. In electrical systems where busbars may experience high - current loads, the ability to transfer heat effectively prevents overheating, which can otherwise cause damage to the busbar and other connected components. In data centers, where continuous power supply is crucial and heat management is a challenge, copper busbars can assist in maintaining optimal operating temperatures.

3.Good Corrosion Resistance: Copper has a relatively high resistance to corrosion. It forms a thin, protective oxide layer on its surface when exposed to air, which helps to prevent further oxidation and degradation. This makes copper busbars suitable for use in a variety of environments, including those with moderate humidity. However, in highly corrosive environments, such as near chemical plants or in coastal areas with high salt - air content, additional protective measures may still be required.

Mechanical Strength and Malleability: Copper possesses good mechanical strength, allowing it to withstand the mechanical stresses associated with installation and operation. At the same time, it is malleable, which means it can be easily shaped into the required form for busbar applications. This malleability simplifies the manufacturing process and enables the production of busbars with precise dimensions and complex shapes to meet different installation requirements.

Aluminum

1.Cost - Effectiveness: One of the primary advantages of aluminum as a busbar material is its cost - effectiveness. Aluminum is more abundant and generally less expensive than copper, making it an attractive option for applications where cost is a significant factor. In large - scale power distribution projects with tight budgets, using aluminum busbars can result in substantial cost savings without sacrificing too much on performance.

2.Low Density: Aluminum has a low density compared to copper. This makes aluminum busbars lighter in weight, which can be advantageous in certain applications, especially when ease of installation and reduced structural load are important considerations. For example, in overhead power distribution systems or in installations where the busbars need to be suspended, the lighter weight of aluminum busbars can simplify the installation process and reduce the need for heavy - duty support structures.

3.Sufficient Electrical Conductivity: Although aluminum's electrical conductivity is lower than that of copper, it still offers sufficient conductivity for many electrical applications. With proper sizing and design, aluminum busbars can effectively carry the required electrical current. However, due to its higher resistivity, aluminum busbars may experience slightly higher power losses compared to copper busbars of the same cross - sectional area.

4.Corrosion Susceptibility: Aluminum is more prone to corrosion than copper, especially in the presence of moisture and certain chemicals. When exposed to the elements, aluminum forms a porous oxide layer, which, unlike the protective oxide layer on copper, does not provide the same level of protection against further corrosion. In humid or corrosive environments, special coatings or corrosion - resistant alloys may be required to ensure the long - term reliability of aluminum busbars.

In conclusion, both copper and aluminum have their own unique characteristics as materials for MCB busbars. The choice between the two depends on a variety of factors, including the specific requirements of the electrical system, the operating environment, and the budget constraints. Understanding these material characteristics is essential for making an informed decision to ensure the efficient and reliable operation of MCB busbars in electrical power distribution systems.

GET A QUOTE